Ice cream machines, it is a machine that can mix milk powder, ice cubes, fruits, sugar, etc. into delicious desserts. It can also make ice cream with milk paddle or ice cream powder produced in the factory.

According to the main purpose, it can be divided into industrial ice cream machines used in factory assembly lines and commercial ice cream machines used in the catering industry.

Divided by the shape category of the finished ice cream, ice cream machines are mainly divided into soft ice cream machines and hard ice cream machines.

soft ice cream

A frozen treat has to have at least 10% milk fat to be labeled ice cream, according to the Food and Drug Administration. Ice cream is also churned as it’s frozen to give it a lighter texture.

Gelato

Thanks to using less cream and more milk, gelato has a lower fat content than ice cream. It’s churned slower to give it a dense and creamy texture.

Soft ice cream machine

Soft ice cream is mainly made of cream, egg yolk, milk, sugar, etc. Because it contains more cream, it is very fragrant and silky. In addition, the puffing rate is between 20-80%, and the mouth is smooth and easy to melt.

According to the machine shape, it can be divided into vertical soft ice cream machine and desktop soft ice cream machine; according to taste, it can be divided into single-head, double-head, three-head or multi-head machines. Compared with the market, the three-head machine is the most popular, that is so-called three-color ice cream machine,then followed by Single head, namely single-color ice cream machine.

Single head ice cream machine

The single-head ice cream machine has only one storage tank, one refrigeration cylinder and one discharge port, and can only produce ice cream of one flavor at a time, which is called single-color ice cream machine. Generally suitable for small restaurants, baking shops, coffee shops, western restaurants, hotels, KTV, Internet cafes and other occasions where the output and taste of ice cream are not required. Good performance-price ratio, this kind of ice cream machine is small and exquisite, the weight is between 100-200KGS, and the power is generally between 2000W.

Features are as follows:

- The degree of automation is high. The relevant programs are preset through the control panel, and the machine automatically completes and prompts according to the specified program.

- The mix tank is equipped with a stirrer to avoid layering of the slurry, effectively reduce foam, and try to make each ice cream taste consistent.

- One-piece scraper, no longer to worry about complicated cleaning.

- With a defrosting system, the freezing cylinder can be heated, making cleaning more convenient, sanitary and safer.

- The optional TEOREMA system can provide customers with remote technical support through smart terminal equipment to ensure stable operation of the equipment.

- Small size, light weight, and the rear panel exhausts air to optimize the space.

Three head ice cream machine

There are two storage tanks, two refrigeration tanks and three discharge ports. It can produce ice cream in three colors, namely three flavors, including two pure flavors and one mixed flavor. This ice cream machine is much used in the market The weight is generally 150-500KGS, and the power varies between 1700W-7000W. It is suitable for all kinds of chain restaurants, large supermarkets, ice cream shops, playgrounds, schools, cinemas, baking shops and other occasions that require more ice cream production and taste.

- The degree of automation is high. The relevant programs are preset through the control panel, and the machine automatically completes and prompts according to the specified program.

- The mix tank is equipped with a stirrer to avoid the layering of the slurry, effectively reduce the foam, and try to make each ice cream taste consistent.

- One-piece scraper, no longer have to worry about complicated cleaning.

- With a defrosting system, the freezing cylinder can be heated, making cleaning more convenient, sanitary and safer.

- The optional TEOREMA system can provide customers with remote technical support through smart terminal equipment to ensure stable operation of the equipment.

- With large output and many flavors, it can continuously meet consumer demands.

Baking ice cream machine

Baking ice cream machine, according to the characteristics of the baking market, a product that perfectly combines with bakery products. It is suitable for dessert bakery shops that have already started making cakes and mousses, which can effectively improve efficiency, save manpower, economy and hygiene; at the same time, it is very suitable for bakery shops that have not yet developed cakes, mousse and other businesses, and it can effectively increase the commercial added value of a single store . Features are as follows:

- With pasteurization, it only needs to be cleaned once in 14 days and only about 25 times a year, which can reduce the staffing of the bakery.

- According to the characteristics of the bakery shop, it adopts a long discharge tube, which is suitable for making desserts with molds, such as cakes and mousses. It is very suitable for the baking industry to improve efficiency and save labor.

- Specially customized for the baking industry, a multi-purpose ice cream machine that can make soft ice cream, gelato sorbet, dessert, sorbet, gelato cake, cream dessert, mousse and cream, etc.

- Special dessert machine, capable of producing 2 different desserts at the same time.

- The optional TEOREMA system can provide customers with remote technical support through smart terminal equipment to ensure stable operation of the equipment.

- You can make desserts at night and sell ice cream multi-purpose machines during the day.

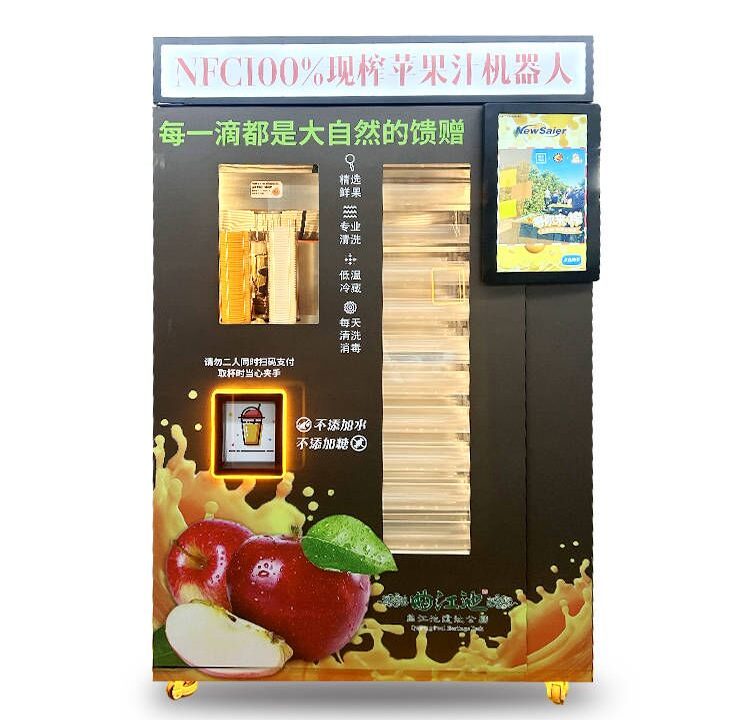

Automatic ice cream vending machine

This is an ice cream vending machine full of magic. It does not require manual labor, only needs to be placed in a suitable location and cleaned regularly. It is suitable for shopping malls, amusement parks, and stores along the street with a large flow of people. Features are as follows:

- Automatic coin insertion, no need for continuous care by a dedicated person, just regular feeding and cleaning, which effectively reduces manpower and increases added value

- WithUV sterilization, it only needs to be cleaned once in 14 days and about 25 times a year, which can reduce the staffing of the bakery.

- Optional TEOREMA system can provide customers with remote technical support through smart terminal equipment to ensure stable operation of the equipment.

- Rapid expansion can be achieved. In shopping malls, amusement parks, and storefronts along the street with a large flow of people, multiple machines can be placed at one time, managed by a dedicated person, and regular inspections and cleaning are enough.

Among the above main types of ice cream machines, you can choose to have a pump or a self-flow type, and a pasteurized ice cream machine according to your needs.

- Features of pump and self-flow ice cream machine:

The machine with air pump increases the air content in the ice cream and increases the puffing rate. The puffing rate can reach between 40-80%, making the ice cream more delicate and smooth. Generally, most businesses in the market will choose this type of machine from the comprehensive factors such as taste and cost.

The self-flowing ice cream machine mainly relies on the gravity flow of raw materials, and the puffing rate can reach up to 40%. The texture of ice cream is relatively hard, which is more suitable for making chocolate and yogurt ice cream.

- Features of pasteurized ice cream machine:(New Saier ice cream vending machines without pasteurized function)

In the conventional soft ice cream machine, the high temperature disinfection function is added. The conventional machine can be cleaned once in 3 days, and the pasteurized machine can be cleaned once in 14 days. It can more effectively ensure food safety, greatly improve efficiency and save labor. Taking these factors into consideration, generally large chain businesses are more willing to choose machines with this function.

- How to choose the right soft ice cream machine? It can be selected according to the following main points:

- First determine the type of flavor. If it is a single flavor, such as yogurt, matcha and chocolate, you can consider a single-head machine.and for other multi-flavors,wecan choose a three-head machine.

- Secondly, the sales volume is estimated. Based on experience and calculations, the number of cups sold per day is estimated, so that it can be determined whether it is a vertical or a desktop machine. Generally, if the daily sales volume is less than 2,000 copies, you can consider choosing a desktop computer to meet the requirements. The output of the general desktop computer can reach 200-500 copies/hour, which can achieve the highest cost performance; others can consider choosing a vertical machine.

- Finally, according to the characteristics of the product, you can choose the pump or self-flow type. If it is a single flavor, such as yogurt and chocolate, you can consider the self-flow type machine is more suitable. Others consider the taste and cost, and you can choose the pump machine.

- In addition, for comprehensive considerations such as hygiene and safety, efficiency improvement, manpower saving and management convenience, consider choosing a pasteurization machine.

- Buy famousbrand machines from reliable factories, so that there are fewer problems in the production process, good continuous stability, longer service life, and better taste.

Now let’s check the working principle of ice cream vending machine from New Saier:

First, the raw materials are added to the raw material tank, and then the raw materials and air are uniformly mixed and sent to the freezing cylinder under the action of the air slurry pump, and the expanded milk slurry is stirred and gradually cooled. The viscosity of the freezing cylinder increases. When it reaches the required viscosity, it is pushed to the outlet by the screw auger, the outlet is opened, and the machine extrudes the finished ice cream.

The raw materials of ice cream:

- Ice cream powder

It is the most widely used and most common ingredient for ice cream. Ice cream powder is usually mixed with water in a certain ratio. Since the aging process is usually not required, it is convenient to use, easy to transport and store. However, care should be taken to avoid secondary pollution during the mixing process.

- Fresh milk sauce

Generally, the shelf life is about one week, and the production and transportation links are deleted. The guarantee period for guests is approximately 4 days. However, due to different brands, different processing methods, and different shelf life. At the same time, you need to keep the refrigerator to make the mixture taste better.

- Fresh milk

It adopts aseptic packaging and does not require refrigeration, which is convenient for storage and transportation.

- Ice cream ice cream powder

Different flavors of hard ice cream powder: milk flavor, vanilla flavor, chocolate flavor, strawberry flavor, pineapple flavor, cantaloupe flavor, toon flavor, mango flavor, peach flavor, lemon flavor, green apple flavor.

Daily maintenance of ice cream vending machine: 配图

- Clean the cold storage tank

In order to ensure the health of ice cream consumers and increase the service life of machine parts, you must clean the refrigerator once a day.

(1) Press the cleaning button to drain all the slurry in the water tank, and then press the stop button.

(2) Add disinfectant with warm water and pour it into the bucket. The amount of water in the second bucket is the same.

(3) Use the cleaning button to stir for about 1-2 minutes to drain the cleaning solution.

(4) Wash 2-3 times with water and stop.

(5) Turn off the power and remove all parts.

- Body cleaning

Consumers need beautiful, clean, and hygienic machines. Please keep your body clean at any time. You can wipe your body with a warm towel to remove stains. Do not flush with water to avoid equipment failure.

- Clean the condenser

During operation, the condenser will be covered by dust and affect heat dissipation. The cooling effect is poor. The specific cleaning time may vary from three to six months, depending on the operating environment. Turn off the power before cleaning. Do not damage the condenser fins and use a soft brush. It can be cleaned with a hair dryer.

- Drive adjustment

After the machine is used for a long time, the transmission belt of the mixing system may stretch and require adjustment. The belt slips and the machine stops suddenly after a period of time. “NL” will be displayed on the digital tube of the Northeast series soft ice cream machine. The buzzer emits a long and regular intermittent sound. At this time, please disconnect the power supply, remove the left side panel of the machine, and then use a wrench to adjust the screws fixed under the motor. In this case, the machine is not malfunctioning. The machine must be turned off before adjusting the belt. After the power is turned on and the belt is turned off, the machine returns to normal.

New saier uses high-tech technology to combine unmanned sales and new retail, and is an enterprise with deep cultivation in sub-industry fields, integrating R&D, production, operation, sales, and marketing. It insists on innovative design, high-tech applications and stable quality performance to provide professional demand solution services for brand operators, chain enterprises, and entrepreneurs, making entrepreneurship easier. At present, the scope of new saier high-tech services has spread to many countries around the world, such as United States, Australia, Poland, Serbia, Germany, etc.